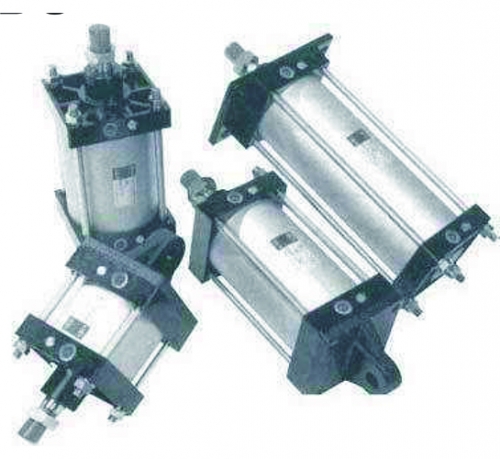

One of the important components of pneumatic components is the cylinder, in order to ensure the normal use of the cylinder prevent unnecessary conditions, for the use of pneumatic components, let's look at the use of pneumatic components.

When using cylinders, the requirements for air quality are very high. Clean dry compressed air should be used. The air must contain synthetic oils, salts, corrosive gases of organic solvents to prevent poor operation of cylinders valves. Before installation, the connection piping should be fully flushed, do bring impurities such as dust, swarf, sealing tape fragments into the cylinder valve. In places with a lot of dust, water droplets, oil droplets, a telescopic protective cover should be provided on the side of the rod. During installation, no twisting

state should occur . When the telescopic protective sleeve cannot be used, use a cylinder with a strong dust ring a waterproof cylinder.

Standard cylinders must be used in corrosive mists in mists that cause the seal ring to swell. Lubricating cylinders should be equipped with a lubricator with a reasonable flow rate. Lubricating cylinders should be lubricated because of the pre-filled grease in the cylinder, which can be used for a long time. This type of cylinder can also be used for oil, but once the oil is supplied, the oil supply must be stopped, because the pre-lubricating grease may have been flushed out, failure to supply oil will cause the cylinder to malfunction.

At the installation site of the cylinder, it is necessary to prevent the swarf of drilling holes mixing into the air inlet of the cylinder. The cylinder cannot be used as a gas-liquid combined cylinder to prevent oil leakage. The sliding parts of the cylinder barrel the piston rod must be damaged to prevent the cylinder malfunctioning damaging the piston rod seal ring to cause air leakage.

Appropriate maintenance adjustment space should be reserved at the buffer valve, proper installation adjustment space should be reserved for the magnetic switch. If the cylinder is used for a long time, it should be operated once a month, oiled to prevent rust.

Pneumatic components are widely used in the field of public facilities, such as the ventilation equipment, remote control valves, pneumatic switch control of thermal power stations such as boiler rooms; the interlock between fuel absorber feed devices of nuclear power plants, feed inlets manual air locks, Test metering devices, automatic operation; water level control of water supply systems, remote control valves, operation of target gear screens control valves in sewers wastewater treatment; auxiliary of mining industry to directly indirectly mine ores in open underground mines Equipment etc.